The Beta Prototype

Although progress slowed during late 2024 and early 2025, due to various real life issues, in August 2025, we got back on the Beta Prototype.

Cabinet: Two bodies have been built of different materials. One is the classic figured Maple (I mean, how could we not?). The other is of a different material, veneered in Wenge. Read more about the rationale for two prototypes below.

Maple body.

Wenge veneered body.

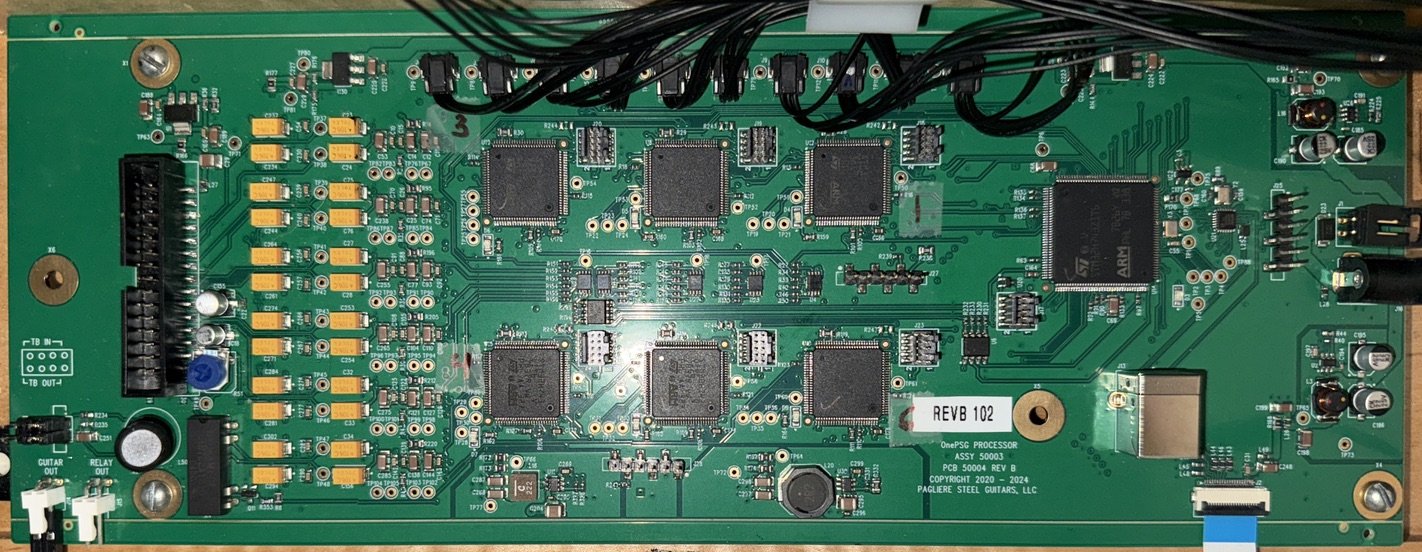

Main PCB

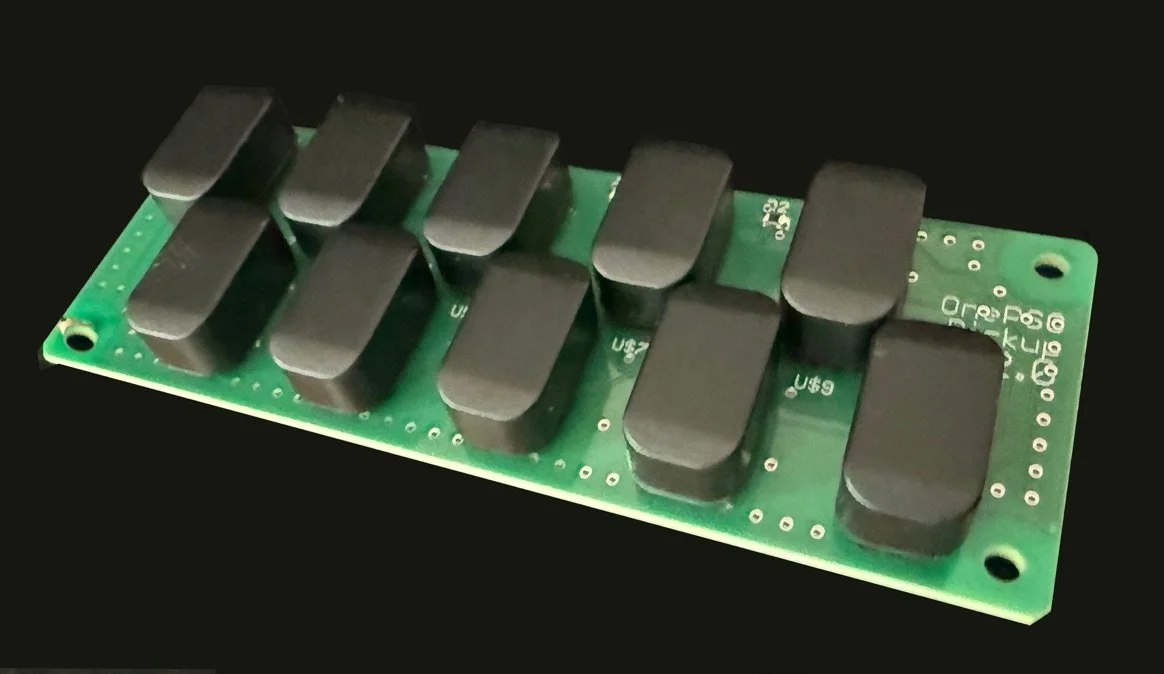

Pickup PCB with Nu pickups

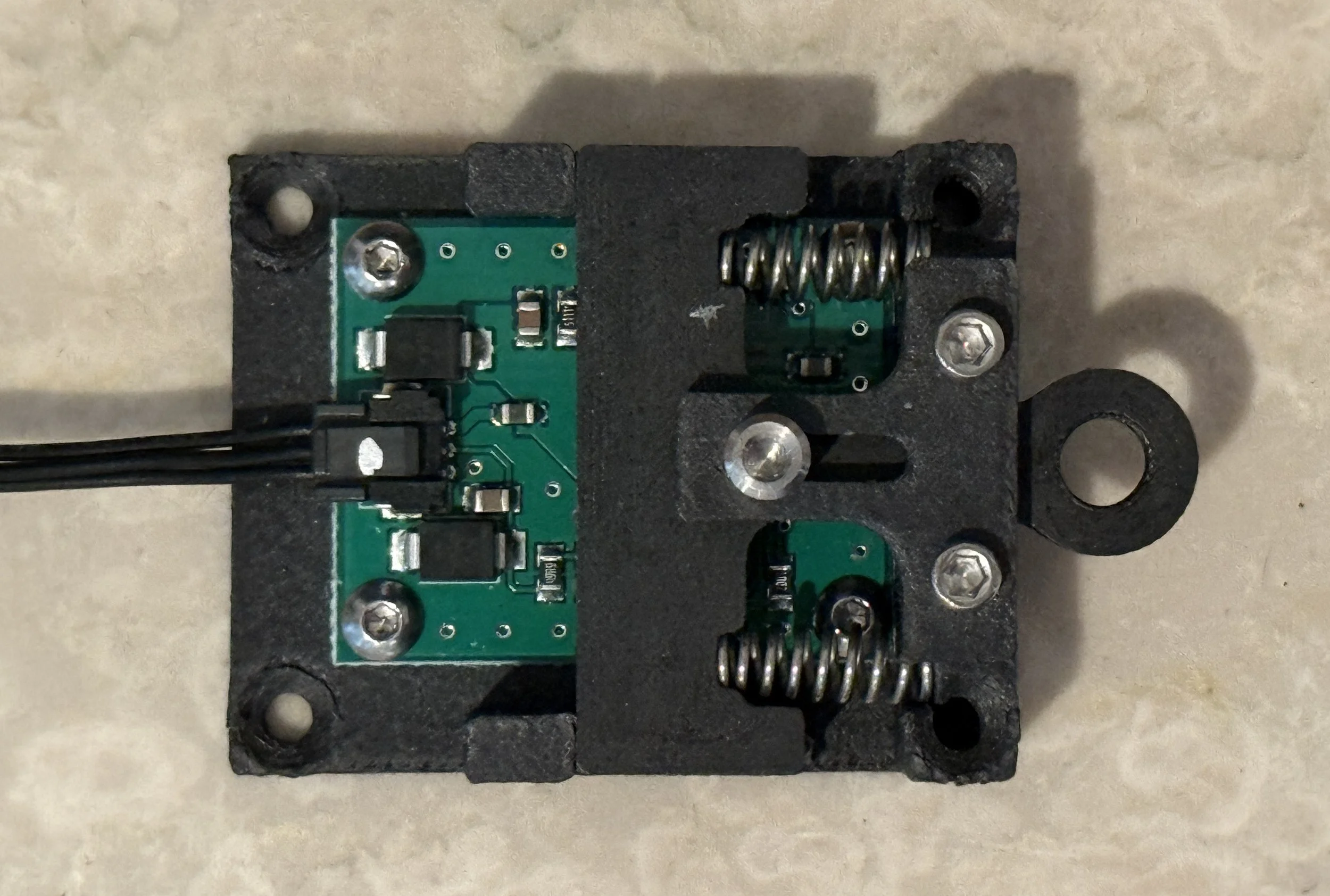

Sensor Assembly with PCB

Electronics: The main circuit board handles all control and signal processing functions. It has been redesigned based on what we learned from the Alpha Prototype and is ready for use. Pickup PCB and Sensor PCBs are assembled and ready.

Final cables and cable assemblies purchase, January 2026.

Machined parts: Custom endplates are finished.

Machined and 3D printed mechanical parts (not pictured) are in different stages of design and production.

Software: Control software (some of which is patented) has been enhanced with added functionality and new hardware control.

The digital signal processing (DSP) software has been updated as well.

View of endplate

The rationale for two Betas: Firstly, it will be useful to have one instrument for continued testing while a second can make the rounds among several pedal steel players for real world testing and "user feedback."

Secondly, as mentioned above, the cabinets of the two instruments are built of different materials. One is curly maple to be somewhat traditional.

As for the second instrument? As described in other parts of this website, the pitches coming from the amp or headphones are not the same as the low volume sounds one might hear acoustically from the strings or body.

Even though at a very low amp output, the acoustic sounds are not heard, we want to lose as little of the physical strings' energy through the body as possible, since that is energy not making it into the pickup. We're using a different material on the second instrument in order to reduce that loss of the strings' vibrational energy into the body. The idea is to have as low an acoustic volume as possible. The whole exercise is a kind of A/B test of cabinet material.